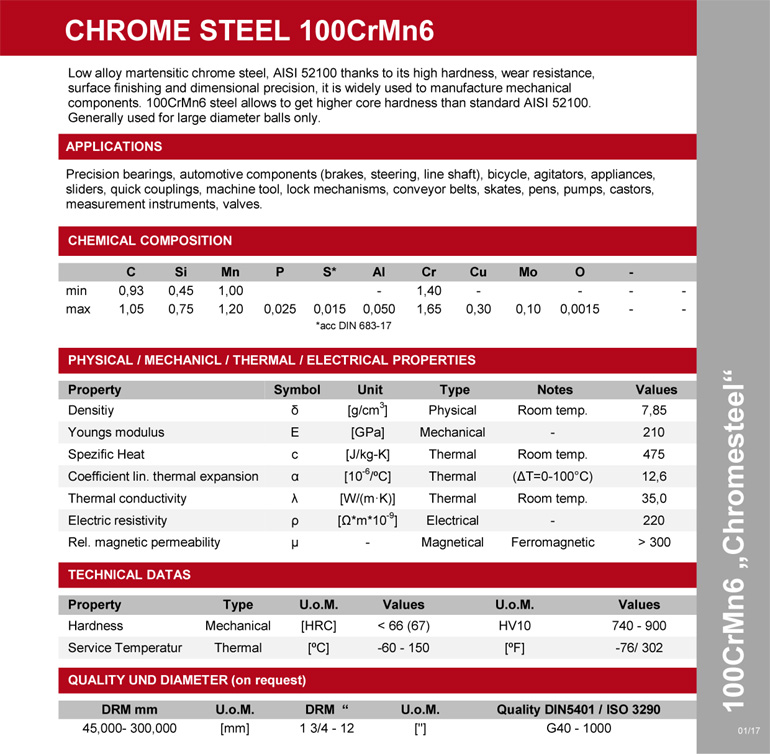

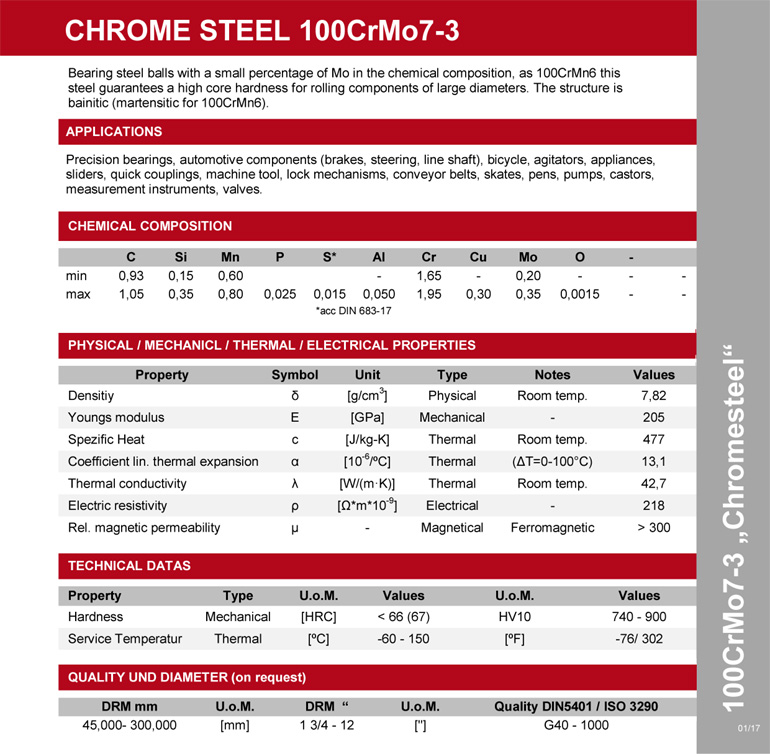

These are two alternative materials for balls with larger diameters. This material is generally not a stock item and must always be requested and produced separately.

These materials are also rolling bearing steels from which balls, cylindrical rollers and needle rollers can be manufactured. The only difference between these materials and chromium steel 1.3505 is their hardenability. All other properties are almost identical.

100CrMn6

1.3536 – 100CrMo7

Unfortunately, this material is very difficult to obtain in small quantities and the demand for rolling elements made from it is not very high. For this reason, chrome steel 1.3505 is used almost exclusively in the production of our standard balls and rollers and the associated drop in hardness in the core is accepted.